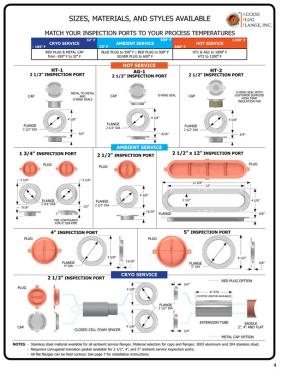

Standard Temperature Service

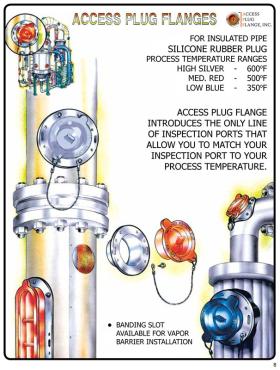

By 'matching the inspection port to your process temperature', you can protect the integrity of the system from failure due to the loss of the insulation core.

As with all inspection ports, we recommend that after installation, some type of insulation material is inserted inside the 'inspection chamber' as the final step. In the event that the insulation material is lost or discarded during the inspection process, the back side of the inspection port will be subjected to the heat being radiated off of the surface of the pipe or vessel. If the inspection port is not rated for that temperature, heat failure of the stopper is possible. Once stopper failure occurs, water and air can penetrate into the inspection chamber and form surface corrision that can lead to expensive repair costs or worse, critical failure.

Our inspection ports were specifically designed to protect against port failure from just such an event.

By using one of the inspection ports shown below within the listed operating temperatures, if the insulation material is lost or discarded, the integrity of the system is protected. We recommend you view our 'Inspection Ports' page if you haven't already for more information about the advantages of using APF's inspection ports over the competition.

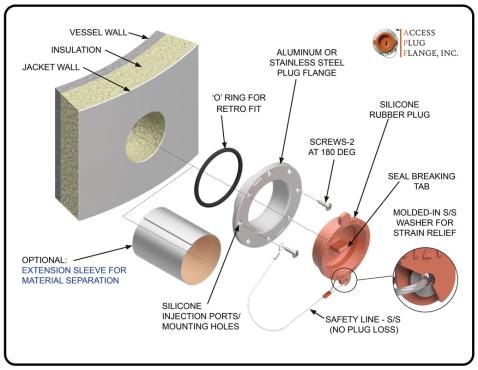

- A hole saw is NOT required for installation, this prevents possible damage to the base metal from the hole saw pilot bit or accidental damage to hidden trace lines

- The inspector is shielded from the cut edge of the jacketing by the center draw of the flange, this allows you to comply with OSHA safety requirements

- Silicone applied under the flange is what provides the primary holding and sealing capabilities for the flange to the jacketing surface

- The elasticity of the large volume of silicone under the flange is what helps maintain the airtight and watertight seal during any thermal expansion or contraction of the jacketing material

- When installed per manufactures recommendation, a permanent airtight and watertight seal will be achieved

- 1/2" banding slots are provided in the flange to allow the inspection port to be banded in place when required

- Based on the application needed, all flat flanges can be field contoured to conform to a smaller radius.

- The silicone plug is designed with a convex bottom to provide long-term sealing pressure against the side wall of the flange to compensate for any shrinkage from aging

- Optional Separation Sleeve for material separation is available

- Optional Stainless Steel Flange is available for use in corrosive environments

- Optional Stainless Steel Sleeve is also available

Available Sizes

| Part Number | Description | Working Hole Size for Inspectors | Minimum Temp Range | Max Temp Range | Flange Material | Stopper Material | |

| 1111102 | 1 3/4" APF Assembly, Aluminum Flat Flange, Red Silicone Access Plug w/Copper Sleeve | 1 3/4" | 33°F | 500°F | Aluminum | Silicone | |

| 1121102 | 1 3/4" APF Assembly, Aluminum Contoured Flange, Red Silicone Access Plug w/Copper Sleeve | 1 3/4" | 33°F | 500°F | Aluminum | Silicone | |

| 1111103 | 2 1/2" APF Assembly, Aluminum Flat Flange, Red Silicone Access Plug w/Copper Sleeve | 2 1/2" | 33°F | 500°F | Aluminum | Silicone | |

| 1111104 | 4" APF Assembly, Aluminum Flat Flange, Red Silicone Access Plug w/Copper Sleeve | 4" | 33°F | 500°F | Aluminum | Silicone | |

| 1111105 | 5" APF Assembly, Aluminum Flat Flange, Red Silicone Access Plug w/Copper Sleeve | 5" | 33°F | 500°F | Aluminum | Silicone | |

| 1111106 | 2 1/2" x 12" APF Assembly, Aluminum Flat Flange, Red Silicone Access Plug w/Copper Sleeve | 2 1/2" X 12" | 33°F | 500°F | Aluminum | Silicone | |

| 1211102 | 1 3/4" APF Assembly, Stainless Steel Flat Flange, Red Silicone Access Plug w/Copper Sleeve | 1 3/4" | 33°F | 500°F | Stainless | Silicone | |

| 1221102 | 1 3/4" APF Assembly, Stainless Steel Contoured Flange, Red Silicone Access Plug w/Copper Sleeve | 1 3/4" | 33°F | 500°F | Stainless | Silicone | |

| 1211103 | 2 1/2" APF Assembly, Stainless Steel Flat Flange, Red Silicone Access Plug w/Copper Sleeve | 2 1/2" | 33°F | 500°F | Stainless | Silicone | |

| 1211104 | 4" APF Assembly, Stainless Steel Flat Flange, Red Silicone Access Plug w/Copper Sleeve | 4" | 33°F | 500°F | Stainless | Silicone | |

| 1211105 | 5" APF Assembly, Stainless Steel Flat Flange, Red Silicone Access Plug w/Copper Sleeve | 5" | 33°F | 500°F | Stainless | Silicone | |

| 2143001 | 2 1/2" Heat Check Assembly (HT-1), Aluminum Flat Flange, Deep Draw Aluminum Cup w/Copper Sleeve | 2 1/2" | 33°F | 1,000°F | Aluminum | Aluminum | |

| 3153002 | 2 1/2" Heat Check Assembly (HT-2), Aluminum Flat Flange, Shallow Draw Aluminum Cup w/Copper Sleeve, Stainless Steel Pin & Washers | 2 1/2" | 33°F | 1,200°F | Aluminum | Aluminum | |

| 4163003 | 2 1/2" Aerogel Assembly (AG-1), Aluminum Flat Flange, Shallow Draw Aluminum Cup w/Copper Sleeve | 2 1/2" | 33°F | 1,000°F | Aluminum | Aluminum |

APF Installation Advantages

APF Inspection Port installation is quick and safe because they attach to the jacketing surface and not to the cut edge. This provides a multitude of benefits as detailed below.

No Hot Work Permit Needed

Since we attach to the jacketing surface and not to the cut edge of the jacketing, a hole saw is NOT required thus eliminating the need to acquire a hot work permit. Since a hot work permit is not required, multiple installers can be working in different areas at the same time. This helps to lessen some of the installation costs by shortening the overall installation time by using multiple installers and also, in the event scaffolding has to be rented and erected, the rental and installation period can be shortened.

Since a hot work permit is NOT required, a shutting down of the process prior to installation is NOT required. Since you are not using a hole saw. Installation of our inspection ports can be performed while the unit is in production since there is no chance of piercing the base metal.

The biggest benefit of not using a hole saw is you lesson the chance of the installer damaging any trace lines that could be under the insulation, or worse, having the installer accidentally drilling through the base metal with the pilot bit of the hole saw.

Protection Against Packeting Expansion/Contracting

When the seal between the inspection port and the jacketing is made by using the interference fit along the cut edge of the hole, the seal can be compromised if the jacketing material expands or contracts after installation. If the inspection port were installed when the temperature was very cold, the cut hole could be become larger once the jacketing expanded because of a temperature increase. ANY expansion of the jacketing could cause the original seal to fail. This failure could allow air or water to breach the seal and penetrate the inspection chamber and get under the insulation. This air/water penetration would allow the conditions to occur that can cause corrosion (CUI). This also applies if the jacketing contracts after installation. ANY contraction could cause a very slight buckle in a soft sided flange. Any type of buckling could also cause the original seal to fail and create the same CUI conditions.

Because of these possible conditions, any installation where the jacketing is cut open should be sealed with a high grade silicone to prevent any type of air or water breach. By sealing to the jacketing surface with the largest sealing area in the industry, we can protect AGAINST any thermal expansion or contraction of the jacketing material after installation.

Explore Related Products

Our High Temperature & Thin Insulation Inspection Ports also works well for the temperature range of 33°F to 500°F / 1°C – 290°C

Have a Question?

* Denotes a required fieldSend us a message and our team of experts will get back to you shortly with a prompt response.