Cryogenic Service Inspection Ports

With many industrial and medical applications of cryogenic liquids transportation along pipeline and vessels; APF offers two cryogenic inspection ports, from -185°F to 32°F, that helps monitor corrosion under insulation (CUI) and maintains production system integrity.

Cryogenic service inspection ports carry APF's technology as a most insulation effective, maximum inspection area, and most reliable sealing mechanism on market (see Inspection Ports page Advantages section).

RED CRYO and METAL CRYO inspection ports have extended hours of safe production operations for on-surface pipeline plants across a variety of industries such as petrochemical, refining, food processing, and medical. Only cryogenic inspection ports on the market.

For more information about installation and testing please click here.

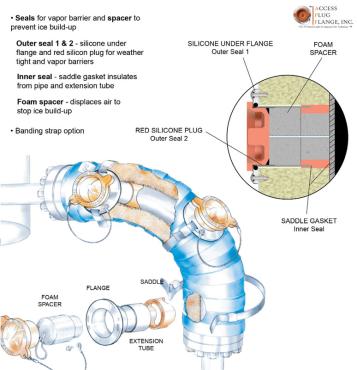

Red Cryo

- Outer seal 1, silicone under flange primary holding and sealant to jacketing

- Inner seal, silicone saddle gasket insulates port from pipe

- Outer seal 2, red silicone rubber plug for weather tight barrier

- Closed cell foam spacer displaces air between inner and outer seals to stop ice build-up

- During inspection to help with ice build-up spray non-toxic propylene glycol antifreeze | 50/50 MIX = -70°F | not a hazardous chemical

- For insulated cryogenic pipe and vessel with safety interlocking metal cap. Orange 'O'-ring seal, silicone under metal flange, and silicone saddle gasket for vapor barrier seals to prevent ice build-up and protect assets.

- Closed cell foam spacer helps displace humid air from port to stop ice build-up

- Process temperature range -185°F to 32°F

- Large silicone seal area under flange eliminates for jacketing cutout errors during installation, provides long-term water and vapor proof seals, and largest holding power in industry.

Available Sizes

| Part Number | Description | Working Hole Size for Inspectors | Minimum Temp Range | Max Temp Range | Flange Material | Stopper Material | |

| 1111111 | 2 1/2 Cryogenic Assembly, Aluminum Flat Flange, Red Silicone Access Plug w/Copper Sleeve, 2 Part Ethafoam Spacer, Flat Saddle, Gasket, 6" OAL | 2 1/2" | -185°F | 500°F | Aluminum | Silicone |

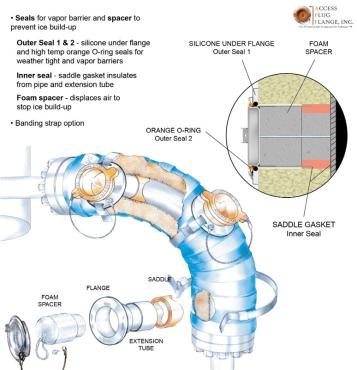

Metal Cryo

| Insulation Thickness [in] | Temperature [°F] | Port Ø [in] | Contour | Material | Condition |

| > 1" | -185°F to 32°F | 2 ½ | Field | Al | Severe | Normal |

- Outer seal 1, silicone under flange primary holding and sealant to jacketing

- Metal cap for efficient ambient cooling

- Inner seal, silicone saddle gasket insulates port from pipe

- Outer seal 2, orange 'O' ring weather tight seal

- Closed cell foam spacer displaces air between inner and outer seals to stop ice build-up

- During inspection to help with ice build-up spray non-toxic propylene glycol antifreeze | 50/50 MIX = -70°F | not a hazardous chemical

- For insulated cryogenic pipe and vessel with silicone red plug, silicone under metal flange, and silicone saddle gasket for vapor barrier seals to prevent ice build-up and protect assets.

- Closed cell foam spacer helps displace humid air from port to stop ice build-up

- Process temperature range -185°F to 32°F

- Large silicone seal area under flange eliminates for jacketing cutout errors during installation, provides long-term water and vapor proof seals, and largest holding power in industry.

Available Sizes

| Part Number | Description | Working Hole Size for Inspectors | Minimum Temp Range | Max Temp Range | Flange Material | Stopper Material | |

| 1111222 | 2 1/2 Cryogenic Assembly, Aluminum Flat Flange, Shallow Draw Aluminum Cup w/Copper Sleeve, 2 Part Ethafoam Spacer, Flat Saddle, Gasket, 6" OAL | 2 1/2" | -185°F | 500°F | Aluminum | Aluminum |

Have a Question?

* Denotes a required fieldSend us a message and our team of experts will get back to you shortly with a prompt response.