APF offers two types of labels for non-insulated equipment: (1) inspection labels to identify inspection points on non-insulated pipes and vessels, and (2) vibration labels to identify inspection points on rotational equipment.

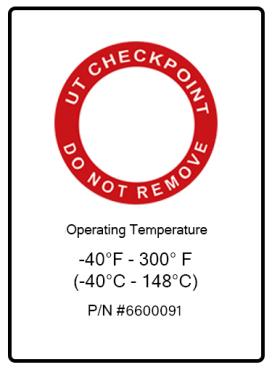

Inspection Point Labels

All successful NDT programs require Inspection Point Labels. The monitoring of both insulated and non-insulated areas is an absolute necessity for a complete NDT program. Our Inspection Point labels will aid in tracking your inspection points on all your non-insulated piping and vessels. Each Inspection Point label measures 1 3/8" in diameter with a 3/4” center hole for surface availability and is resistant to chemicals such as isopropyl alcohol, detergents, engine oils and water.

Inspection Point Label

Product Specifications

- Adhesive is a high performance acrylic for strong bonding, even on textured surfaces.

- Over laminate is 3.5 mil of matte silver mylar polyester material. Matte coating is resistant to degradation from scuffing, chemicals, moisture and wide temperature fluctuations.

- Operating temperature range is between -40°F and 300°F.

- Leachable chloride, fluoride and sulfur in the adhesive, as measured by Ion Chromograph -PPM- is 3, less than one, and less than one, respectively.

Inspection Point Label

Application Instructions

For optimum adhesion, the application surface must be clean and dry and should be at room temperature or slightly higher. A cleaning agent, such as isopropyl alcohol or heptane, should be used to remove any loose dirt, grease or film from the application surface. Initial bonds are achieved through applied pressure while a higher initial bond can be achieved through a higher rub down pressure. 100% bond strength will be achieved over a two week period.

Please consult the manufacture’s Material Safety Data Sheet (MSDS) for proper handling and storage of any solvents used.

APF can custom design different colored labels for your needs. Contact us today for available colors and pricing.

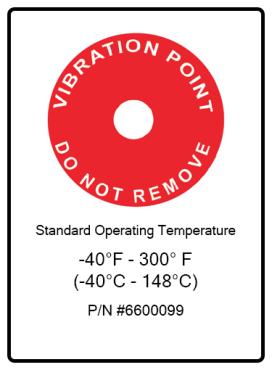

Vibration Point Labels

Access Plug Flange, Inc. manufactures Vibration Point Labels to meet the growing needs of companies testing their rotary motors. These motors have a very steep replacement cost so inspection programs have become the most cost-effective solution. Testing a motor's harmonics has become crucial to a rotary motor's longevity. Each Vibration Point label measures 1 3/8" in diameter with a 3/8" center hole for surface availability and is resistant to chemicals such as isopropyl alcohol, detergents, engine oils and water.

Vibration Point Label

Product Specifications

- Adhesive is a high performance acrylic for strong bonding, even on textured surfaces.

- Over laminate is 3.5 mil of matte silver mylar polyester material. Matte coating is resistant to degradation from scuffing, chemicals, moisture and wide temperature fluctuations.

- Operating temperature range is between -40°F and 300°F.

- Leachable chloride, fluoride and sulfur in the adhesive, as measured by Ion Chromograph -PPM- is 3, less than one, and less than one, respectively.

Vibration Point Label

Application Instructions

For optimum adhesion, the application surface must be clean and dry and should be at room temperature or slightly higher. A cleaning agent, such as isopropyl alcohol or heptane, should be used to remove any loose dirt, grease or film from the application surface. Initial bonds are achieved through applied pressure while a higher initial bond can be achieved through a higher rub down pressure. 100% bond strength will be achieved over a two week period.

Please consult the manufacture’s Material Safety Data Sheet (MSDS) for proper handling and storage of any solvents used.

APF can custom design different colored labels for your needs. Contact us today for available colors and pricing.

Have a Question?

* Denotes a required fieldSend us a message and our team of experts will get back to you shortly with a prompt response.