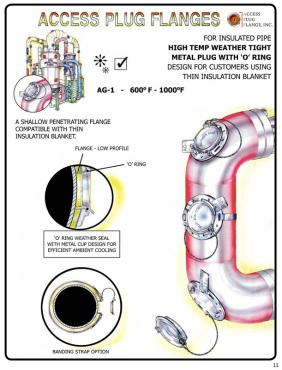

Thin & Light Insulation Port Service

The newest technology in insulation materials is the thin, nano-technology insulations such as Aerogel. This insulation material allows you to have a thinner insulation thickness since you can use less material to achieve the same insulation values. When using this material it is common to have an insulation thickness of less than 1 inch overall With a typical application calling for 2 to 3 wraps of a 5mm material giving you an overall thickness of between 1/2" to 3/4", this can create a problem when using our standard inspection ports where the flange has a center draw of approx 1 inch.

APF now offers an inspection port that helps monitor corrosion under insulation (CUI) for insulated applications with less than one-inch thickness.

The AG1 inspection port was specifically designed for use when your insulation thickness is less than 1 inch by having a shorter center draw on the flange. The AG1 inspection port combines the benefits of both the HT1 and HT2 and allows you to protect the integrity of the system when using this type of insulation material.

Please note that when using this type of insulation material, if your application calls for an installation that ultimately creates an insulation thickness of GREATER than 1 inch, you can use any of the inspection ports listed on our Standard Service page as long as the listed temperature range falls within the temperature range of your application.

APF Inspection Port Assembly - AG1

- Designed for use when using thin insulation materials that produce an insulation thickness of less than 1 inch after installation

- NO hole saw is NOT required for installation, this prevents possible damage to the base metal from the hole saw pilot bit or accidental damage to hidden trace lines

- The inspector is shielded from the cut edge of the jacketing by the center draw of the flange, this allows you to comply with OSHA safety requirements

- Silicone applied under the flange is what provides the primary holding and sealing capabilities for the flange to the jacketing surface

- The elasticity of the large volume of silicone under the flange is what helps maintain the airtight and watertight seal during any thermal expansion or contraction of the jacketing material

- When installed per manufactures recommendation, a permanent airtight and watertight seal will be achieved

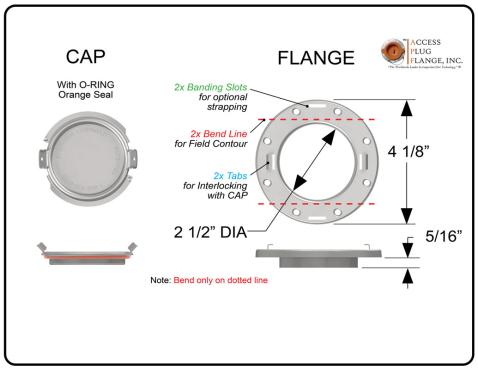

- 1/2" banding slots are provided in the flange to allow the inspection port to be banded in place when required

- Based on the application needed, all flat flanges can be field contoured to conform to a smaller radius

- Outer seal is made using a high temperature o-ring for a weather tight seal

- The metal cup is designed for to provide efficient ambient cooling.

- Only Available in aluminum material and a 2 1/2" diameter

- Optional Separation Sleeve for material separation is available

| Part Number | Description | Working Hole Size for Inspectors | Minimum Temp Range | Max Temp Range | Flange Material | Stopper Material | |

| 4163003 | 2 1/2" Aerogel Assembly (AG-1), Aluminum Flat Flange, Shallow Draw Aluminum Cup w/Copper Sleeve | 2 1/2" | 33°F | 1,000°F | Aluminum | Aluminum |

Explore Related Products

Have a Question?

* Denotes a required fieldSend us a message and our team of experts will get back to you shortly with a prompt response.